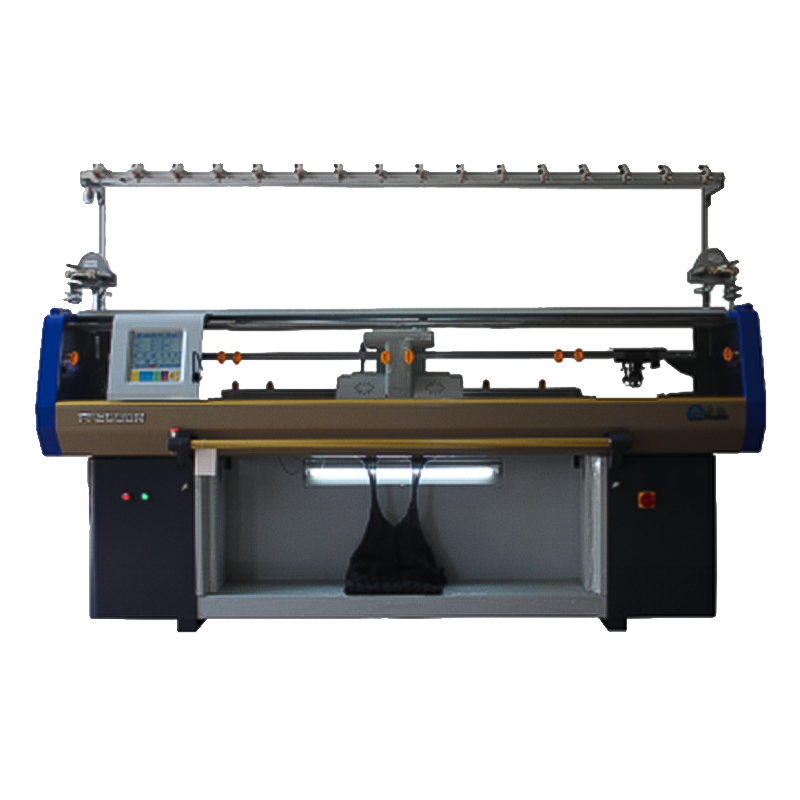

| Stich length/ kiting width Stitch length |

2.5G.3G、 3.5G; |

| Kitting width: |

60/linch) |

| Kitting speed: |

24-section selection selection,maximum speed is up to 1.2m/s.controlled by AC servo-motor.and servo-motor adopts precise feedback control and digital signal processor(DSP),combined with high speed computation capacity to control IGBT to produce precise current output:reading needle signal adopts advanced encoder reading needle. |

| Knitting systm |

single -head triple- system |

| knit function |

knit tranfer,tuck,pointelle, applique jocquard, clear narrowing hidden norrowing and other redular pattern knitting |

| Shift of needle bed |

controlled by AC servo-motor.the needle movement range Is up to 2 inches and accurale function of fine tuning is provided at the same time; |

| Probe alarm system |

probe alarm |

| Rib transfer function: |

triangle composite design. both single/dual synergy con be trnsferred independently or simultaneously, and it can be one system knitting to achieve high fficien production; |

| Stich density |

controlled by stepper motor,24- section densily seleclion,subdlvision technology adopted and 0650 degrees of adjustable range which con control cut-parts lengh more.precisely,to monitor current position of motor by closed-loop system; |

| Sinker system |

controlled by stepper motor,odjusted according to different fabrics, divided into left and right system adjustment;up-down and left-right two control modes to be selected; |

| Balching system |

computer program command.controlled by stepper motor,24- section of tensile force seletion and 0-100 of adjustable range. Thick needle type of machine matches moment.auxiliary roller seleclively to provide effectively to provide effective tensile force for thick cloth product. |

| Color changing system |

1>2* 8 group yorn carrier is configured at both sides of 4 guide rails,which can change yarn carrier(standard configuration 1 8)at any position of needle bed; |

| Control system |

1.LCD industial display is used for screen and the transmission is through USB and network Quantities pattern files can be saved in the system at the some time and can be called |

| 2. Monitoring picture:it can display various working porameters and the kniting stich value,and can de adjusted at any time when machine is running.to provide easy opereration and save time at the moximum lmit; |

| 3.Plala- making System and conteol System are developed independenly,and softwar port updates conveniently and is free coniguraion; |

| 4.Multi-language operation version:it supports Chinese.English and other language versions and can set required language according to requirement of client: |

| Power supply |

single phase 220 V/three phase 380v.it has memory and restoralion function al the powel off moment by using advaanced CMOS technology; |

| Volume/ net weight |

Volumelengthxwidhxheight 3100mmx1000mmx2000mm:net weight is about:1200kg. |

Computerized flat knitting machine series

Multi-wire cutting series

Other series

English

English

中文简体

中文简体

.png?imageView2/2/w/400/h/400/format/webp/q/75)

.png?imageView2/2/w/400/h/400/format/webp/q/75)