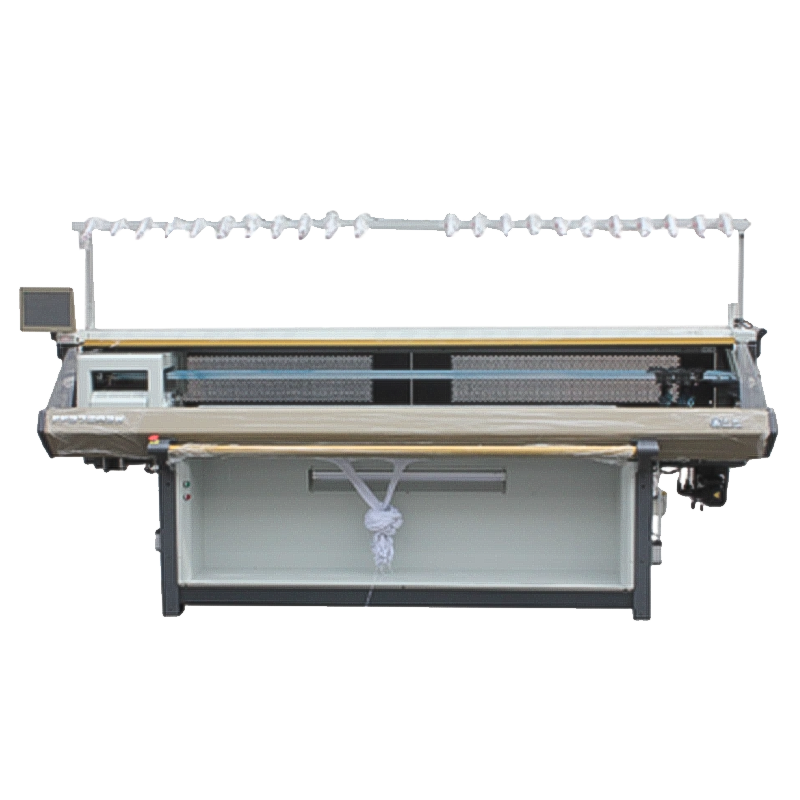

Characteristics:

1. A3 type 18G-8G first use the 4.8inch compound needle-bed rail carriage, each carriage system width narrow by 30mm, to match the 0.05ms high speed return of carriage servo ( such as: for three system machine running with 90 speed, 10 lines save 1 second.) It use 3+2 system, it improves the transfer efficiency and effectively shortens the knitting time to ensures high yield ;

2. The integrated installation of sinker and cam plate of carriage, it ensure the consistency and stability between sinker device and whole carriage, and it is easier for operator to observe the looping process;

3. In the carriage, heavy use the intelligent encoder on the basis of motorized. It can find the zero position intelligently and feedback the position information circularly (it mean when send a command,it will go to finish the command and feedback the result ). It improved the qualification rate of knitwear greatly, customers and maintance staff can use it conveniently;

4. For stitch control, it use the customized motor to accurate it to 0.005mm, it greatly improve the flatness of knitwear ; stitch motor use high speed stepper motor to support varied stitch;

5.The raising cam is controlled seperately, can do pre-select in the middle. The carriage can turn back from the middle when automatic locking, it greatly improved the working efficiency;

6.Colour changing system:2*8 groups of yarn mouth configurations are equipped in two sides of four guide rails for the purpose of shifting the yarn mouth at any position of needle bed( standard configuration 2*8) ;

7. Standard equipped with double racking, it can control racking position accurately and minimize the coil damage which caused by needle bed adjust; the needle bed adjustable function( 3 segments), which is much more help to knit various ribbed patterns and transfer;

8.The high-quanlity batching roller system, the soft upper roller traction which is specially designed, can ensure the posotion closes to the mouth of needle plate, and can reach separate batch in knitting the front and back of whole garment ; It is more efficient to knit open-neck design. it equipped with scissors and clamps, comb device and auxiliary roller.

9. The sole design of sinker self-protection control technology, it ensures that when the needle bed moves left and right, the sinker will not be damaged. With the new sinker control structure (which can adjust up, down, left and right directions) , sinker can control with the yarn perfectly.

10. Separate sinker control system, it makes transfer, knitting and filling ect to be finished in one line.

11.Patentable needle bed gap adjustable function, 14G can working with 1.7mm~2.0mm~2.3mm gap; 7G can working with 3.7mm~4.1mm~4.5mm gap, etc.

System:

1.Adopt the latest A8 high-speed processor, to bring you unparalleled operational experience;

2.LCD industrial display is adopted in the screen, and USB and internet are used as transmission modes. Users can save a great deal of pattern documents and use from time to time in line with the production requirements;

3.Monitoring screen: it is able to display all knids of working parameters and the numerical value for the knitting lines. Meanwhile, it adjusts from time to time at the moment of machine running; therefore it can maximally operate and save time;

4.Platemaking system and control system are researched and developed independently; the software, as the free configuration, can be upgraded conveniently;

5.Multi-Language operation versions: it supports Chinese, English and other languages; meanwhile it can set other required languages as per the customers' requirements;

6.Support design colour code tight tuck 2, support contiguous and multi piece knitted. Stitch can fine adjust seperately and edge correction;

7.Support the function of current detection , provide a warm reminder for maintenance personnel to quickly identify the fault source;

8.Batching system:Computer programs command, stepper motor control,128 segments tension selection. It is able to use auxiliary roller to providing effective tensile force for thick piece of clothes;

9.Support the automatic correction of transfer stitch value, can avoid yarn broken and missed stitch when do tighter knitwear, improved qualification rate of knitwear.

10.With recovery function of factory setting, it can recovery easily when by error operation.

11.The intelligent waste-yarn function, it ensures the minimum use of waste yarn in continuous knitting.

Computerized flat knitting machine series

Multi-wire cutting series

Other series

English

English

中文简体

中文简体

.png?imageView2/2/w/400/h/400/format/webp/q/75)

.png?imageView2/2/w/400/h/400/format/webp/q/75)